Description

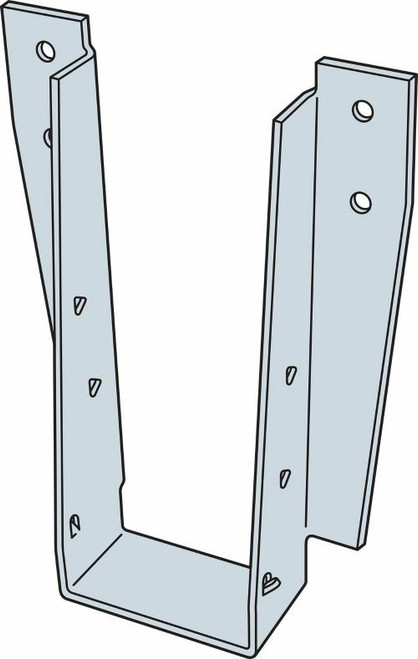

The patent-pending DGF fire wall hanger series features three models and is an ideal time-saving solution for multi-family, multi-level building construction. The hangers easily install on a two-hour wood stud fire wall (e.g., Type III construction) during framing. They feature enough space for two layers of 5/8" gypsum board (drywall) to be slipped into place after the framing is complete. These hangers have been tested according to ASTM E814 and received F (flame) and T (temperature) ratings for use on one or both sides of the wall. These ratings verify that the hangers do not reduce the two-hour fire wall assembly rating.

The DGF is a top-flange hanger that connects floor trusses and joists to wood stud walls. The hanger features a v-shaped joist stop at the top whose unique design prevents the joist from seating too far back in the stirrup, creating space for the drywall to be installed between the joist and the wall after framing. This economical hanger provides joist support for the majority of Type III construction projects.

Key Features

- The two-hour fire wall assembly rating applies to either 2x4 or 2x6 walls

- If hangers are installed back to back on both sides of the wall, the wall must be 2x6

- The DGF has been tested according to ASTM E814 and received F (flame) and T (temperature) ratings that can be found in Intertek Design No. SST/WPCF 120-01

Material

- 12 gauge

Finish

- Zinc galvanized, G90

Installation

- Use all specified fasteners.

- Hangers are mounted like a standard top-flange hanger.

- I-joists require web stiffeners to achieve full table loads. I-joists without web stiffeners have reduced loads as shown in the table.

- When welded to a steel header, the hanger requires four 2" fillet welds along the sides of the top flanges and (6) joist nails to achieve a download of 1,650 lb.; the weld size needs to match the hanger’s thickness.

- Table uplift loads apply to welded applications.

- Stud wall–plate splices must occur at a stud location.

Load Tables

Allowable Loads on 2x4 or 2x6 Wall

| Model | Ga. | Joist Depth (in.) | Fasteners (in.) | Web Stiff Req'd | DF/SP | SPF/HF | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Top | Face | Joist | Uplift (160) | Download (100/125) | Uplift (160) | Download (100/125) | ||||||||

| Studwall | 2x, 3x Nailer | (2) 2x, 4x Nailer | Studwall | 2x, 3x Nailer | (2) 2x, 4x Nailer | |||||||||

| DGF | 12 | 7 1/4 to 11 1/4 | (6) 0.148 x 3 | (4) 0.148 x 3 | (2) 0.148 x 1 1/2 | — | 130 | 1,160 | — | 1,160 | 110 | 1,130 | — | 1,130 |

| (6) 0.148 x 1 1/2 | — | (6) 0.148 x 1 1/2 | 220 | 1,350 | 1,350 | 1,350 | 190 | 1,315 | 1,315 | 1,315 | ||||

| (6) 0.148 x 3 | — | (6) 0.148 x 1 1/2 | 315 | 1,420 | — | 1,420 | 270 | 1,385 | — | 1,385 | ||||

| DGF | 12 | 11 7/8 to 24 | (6) 0.148 x 3 | (4) 0.148 x 3 | (2) 0.148 x 1 1/2 | — | 130 | 1,160 | — | 1,160 | 110 | 1,130 | — | 1,130 |

| (6) 0.148 x 1 1/2 | — | (6) 0.148 x 1 1/2 | 315 | 1,620 | 1,620 | 1,620 | 270 | 1,450 | 1,450 | 1,450 | ||||

| (6) 0.148 x 3 | — | (6) 0.148 x 1 1/2 | 315 | 1,705 | — | 1,705 | 270 | 1,525 | — | 1,525 | ||||

| DGHF | 10 | 9 1/2 to 24 | (5) 0.148 x 1 1/2 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 855 | 2,030 | 2,030 | 2,030 | 650 | 1,855 | 1,855 | 1,855 | |

| (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 900 | 2,135 | — | 2,135 | 770 | 1,950 | — | 1,950 | ||||

| DGBF (over studs) | 7 | 9 1/2 to 24 | (8) 0.148 x 3 | (4) 0.148 x 3 | (8) 0.148 x 3 | 1,040 | 3,015 | — | 3,015 | 890 | 2,280 | — | 2,280 | |

| DGHF (skewed) | 10 | 9 1/2 to 24 | (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 315 | 1,620 | — | 1,620 | 270 | 1,350 | — | 1,350 | |

| DGHF (offset) | 10 | 9 1/2 to 24 | (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 870 | 2,010 | — | 2,010 | 755 | 1,705 | 1,550 | — | |

| ||||||||||||||

The patent-pending DGF fire wall hanger series features three models and is an ideal time-saving solution for multi-family, multi-level building construction. The hangers easily install on a two-hour wood stud fire wall (e.g., Type III construction) during framing. They feature enough space for two layers of 5/8" gypsum board (drywall) to be slipped into place after the framing is complete. These hangers have been tested according to ASTM E814 and received F (flame) and T (temperature) ratings for use on one or both sides of the wall. These ratings verify that the hangers do not reduce the two-hour fire wall assembly rating.

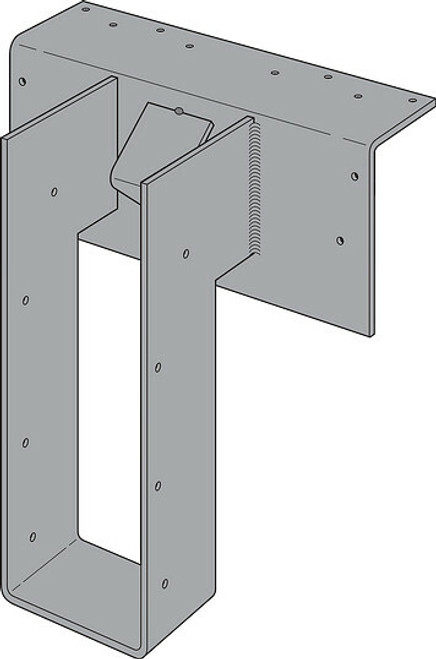

The DGBF is a top-flange hanger specifically designed to connect wood beams to wood stud walls. The hanger features an angled joist stop whose unique design prevents the beam from seating too far back in the stirrup, creating space for the drywall to be installed between the beam and the wall after framing. The DGBF hanger provides support for loads up to 3,015 lb. when installed over a double stud in Type III construction.

Key Features

- The two-hour fire wall assembly rating applies to either 2x4 or 2x6 walls

- If hangers are installed back to back on both sides of a wall, the wall must be 2x6

- The DGBF has been tested according to ASTM E814 and received F (flame) and T (temperature) ratings that can be found in Intertek Design No. SST/WPCF 120-01

Material

- 7 gauge

Finish

- Gray paint

Installation

- Use all specified fasteners.

- Hangers are mounted like a standard top-flange hanger.

- A double stud is required below the hanger.

- When welded to a steel header, the hanger requires two 2" fillet welds along the sides of the top flange and (8) 0.148" x 1 1/2" joist nails to achieve a download of 3,000 lb.; the weld size needs to match the hanger’s thickness.

- Table uplift loads apply to welded applications.

- Apply two 1/4"-diameter beads of fire-resistant mortar caulk directly to top-of-wall plates for the first 6" on either side of top flange. See Intertek design listing for detail.

- Stud wall–plate splices must occur at a stud location.

Load Tables

Allowable Loads on 2x4 or 2x6 Wall

| Model | Ga. | Joist Depth (in.) | Fasteners (in.) | Web Stiff Req'd | DF/SP | SPF/HF | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Top | Face | Joist | Uplift (160) | Download (100/125) | Uplift (160) | Download (100/125) | ||||||||

| Studwall | 2x, 3x Nailer | (2) 2x, 4x Nailer | Studwall | 2x, 3x Nailer | (2) 2x, 4x Nailer | |||||||||

| DGF | 12 | 7 1/4 to 11 1/4 | (6) 0.148 x 3 | (4) 0.148 x 3 | (2) 0.148 x 1 1/2 | — | 130 | 1,160 | — | 1,160 | 110 | 1,130 | — | 1,130 |

| (6) 0.148 x 1 1/2 | — | (6) 0.148 x 1 1/2 | 220 | 1,350 | 1,350 | 1,350 | 190 | 1,315 | 1,315 | 1,315 | ||||

| (6) 0.148 x 3 | — | (6) 0.148 x 1 1/2 | 315 | 1,420 | — | 1,420 | 270 | 1,385 | — | 1,385 | ||||

| DGF | 12 | 11 7/8 to 24 | (6) 0.148 x 3 | (4) 0.148 x 3 | (2) 0.148 x 1 1/2 | — | 130 | 1,160 | — | 1,160 | 110 | 1,130 | — | 1,130 |

| (6) 0.148 x 1 1/2 | — | (6) 0.148 x 1 1/2 | 315 | 1,620 | 1,620 | 1,620 | 270 | 1,450 | 1,450 | 1,450 | ||||

| (6) 0.148 x 3 | — | (6) 0.148 x 1 1/2 | 315 | 1,705 | — | 1,705 | 270 | 1,525 | — | 1,525 | ||||

| DGHF | 10 | 9 1/2 to 24 | (5) 0.148 x 1 1/2 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 855 | 2,030 | 2,030 | 2,030 | 650 | 1,855 | 1,855 | 1,855 | |

| (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 900 | 2,135 | — | 2,135 | 770 | 1,950 | — | 1,950 | ||||

| DGBF (over studs) | 7 | 9 1/2 to 24 | (8) 0.148 x 3 | (4) 0.148 x 3 | (8) 0.148 x 3 | 1,040 | 3,015 | — | 3,015 | 890 | 2,280 | — | 2,280 | |

| DGHF (skewed) | 10 | 9 1/2 to 24 | (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 315 | 1,620 | — | 1,620 | 270 | 1,350 | — | 1,350 | |

| DGHF (offset) | 10 | 9 1/2 to 24 | (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 870 | 2,010 | — | 2,010 | 755 | 1,705 | 1,550 | — | |

| ||||||||||||||

The patent-pending DGF fire wall hanger series features three models and is an ideal time-saving solution for multi-family, multi-level building construction. The hangers easily install on a two-hour wood stud fire wall (e.g., Type III construction) during framing. They feature enough space for two layers of 5/8" gypsum board (drywall) to be slipped into place after the framing is complete. These hangers have been tested according to ASTM E814 and received F (flame) and T (temperature) ratings for use on one or both sides of the wall. These ratings verify that the hangers do not reduce the two-hour fire wall assembly rating.

The DGHF is a top-flange hanger that connects floor trusses and joists to wood stud walls. The hanger features an angled joist stop whose unique design prevents the joist from seating too far back in the stirrup, creating space for the drywall to be installed between the joist and the wall after framing. The DGHF features a top-flange design allowing hangers to be installed and fit together back to back.

Key Features

- All models of the DGHF hanger may be ordered with a skew angle of up to 45° or with the top flange offset left or right

- The two-hour fire wall assembly rating applies to either 2x4 or 2x6 walls

- If hangers are installed back to back on both sides of the wall, the wall must be 2x6

- The DGHF has been tested according to ASTM E814 and received F (flame) and T (temperature) ratings that can be found in Intertek Design No. SST/WPCF 120-01

Material

- 10 gauge

Finish

- Gray paint

Installation

- Use all specified fasteners.

- Hangers are mounted like a standard top-flange hanger.

- I-joists require web stiffeners to achieve full table loads. I-joists without web stiffeners have reduced loads as shown in the table.

- When welded to a steel header, the hanger requires two 2" fillet welds along the sides of the top flange and (8) 0.148" x 1 1/2" joist nails to achieve a download of 3,000 lb.; weld size to match hanger thickness.

- Table uplift loads apply to welded applications.

- Stud wall–plate splices must occur at a stud location.

Load Tables

Allowable Loads on 2x4 or 2x6 Wall

| Model | Ga. | Joist Depth (in.) | Fasteners (in.) | Web Stiff Req'd | DF/SP | SPF/HF | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Top | Face | Joist | Uplift (160) | Download (100/125) | Uplift (160) | Download (100/125) | ||||||||

| Studwall | 2x, 3x Nailer | (2) 2x, 4x Nailer | Studwall | 2x, 3x Nailer | (2) 2x, 4x Nailer | |||||||||

| DGF | 12 | 7 1/4 to 11 1/4 | (6) 0.148 x 3 | (4) 0.148 x 3 | (2) 0.148 x 1 1/2 | — | 130 | 1,160 | — | 1,160 | 110 | 1,130 | — | 1,130 |

| (6) 0.148 x 1 1/2 | — | (6) 0.148 x 1 1/2 | 220 | 1,350 | 1,350 | 1,350 | 190 | 1,315 | 1,315 | 1,315 | ||||

| (6) 0.148 x 3 | — | (6) 0.148 x 1 1/2 | 315 | 1,420 | — | 1,420 | 270 | 1,385 | — | 1,385 | ||||

| DGF | 12 | 11 7/8 to 24 | (6) 0.148 x 3 | (4) 0.148 x 3 | (2) 0.148 x 1 1/2 | — | 130 | 1,160 | — | 1,160 | 110 | 1,130 | — | 1,130 |

| (6) 0.148 x 1 1/2 | — | (6) 0.148 x 1 1/2 | 315 | 1,620 | 1,620 | 1,620 | 270 | 1,450 | 1,450 | 1,450 | ||||

| (6) 0.148 x 3 | — | (6) 0.148 x 1 1/2 | 315 | 1,705 | — | 1,705 | 270 | 1,525 | — | 1,525 | ||||

| DGHF | 10 | 9 1/2 to 24 | (5) 0.148 x 1 1/2 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 855 | 2,030 | 2,030 | 2,030 | 650 | 1,855 | 1,855 | 1,855 | |

| (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 900 | 2,135 | — | 2,135 | 770 | 1,950 | — | 1,950 | ||||

| DGBF (over studs) | 7 | 9 1/2 to 24 | (8) 0.148 x 3 | (4) 0.148 x 3 | (8) 0.148 x 3 | 1,040 | 3,015 | — | 3,015 | 890 | 2,280 | — | 2,280 | |

| DGHF (skewed) | 10 | 9 1/2 to 24 | (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 315 | 1,620 | — | 1,620 | 270 | 1,350 | — | 1,350 | |

| DGHF (offset) | 10 | 9 1/2 to 24 | (5) 0.148 x 3 | (2) 0.148 x 3 | (8) 0.148 x 1 1/2 | 870 | 2,010 | — | 2,010 | 755 | 1,705 | 1,550 | — | |

| ||||||||||||||